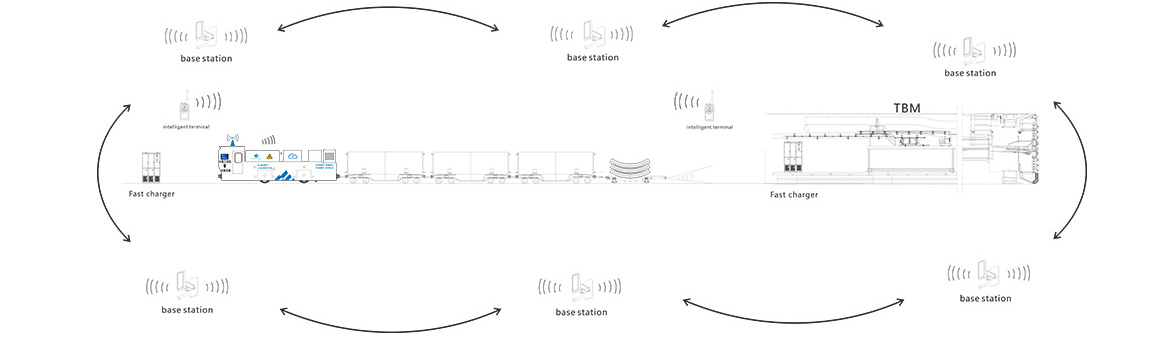

Depend on the technology of conversion, micro-electronics control, high-precision tunnel location and high bandwidth networking, our TBM E-smart locomotive can meet the demand of modern digital tunnel construction.

Wingo central control is an intelligent controller based on the requirements of the E-smart locomotive and actual functional requirements & the safety control strategy of the construction site.

The controller can interchange the information with the locomotive module BMS and control the whole locomotive. Meanwhile, the controller can not only collect, display, analyze and transmit the voice frequency in tunnel on site, but also monitor the locomotive auxiliary control equipment, detect locomotive running speed and gradient, remote control & drive the locomotive , and so on.

To ensure personal and equipment safety, based on the creative design idea of intelligence, safety & efficiency, stable and reliable, our locomotive now has three driving modes---manual, remote control, automatic--- make the tunnel construction more humanization and digitization.

Wingo Power hand intelligent terminal can support multi-standard wireless transmission in high-speed. It has the characteristics of dual-core processor, high stability, high security and high bandwidth. Our tunnel terminal integrates multi-functions of locomotive control, cluster intercom, GIS maps and data transmission.

● Digital, analog dual-channel of 2.4G and 400M, which can give instructions to control the locomotive;

● Built-in precise positioning module, the precision is less than 30cm;

● Protection level (waterproof, dustproof and anti-collision) is IP67(military standard level);

● It can work continuously for 18 hours after it is fully charged;

● Digital reception sensitivity: 0.19μV.

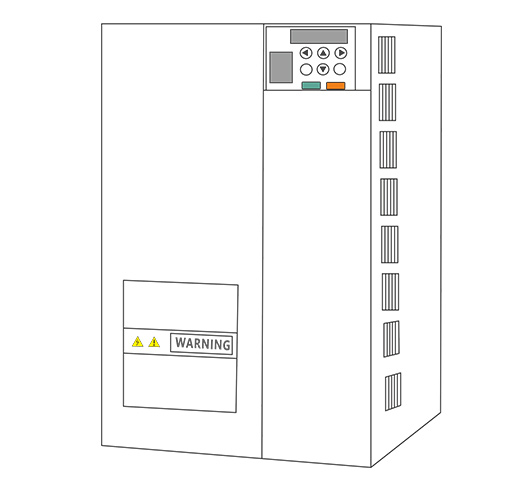

Depend on the technology of frequency conversion and micro-electronics, Wingo Power AI frequency converter can control AC electric motor by changing the frequency of the motor working power, thus realizing the automatic speed regulation of the locomotive.

• Microcomputer intelligent control, automatic frequency conversion, automatic adaptation, automatic follow, manual adjustment is not needed;

• It is easy to control the speed of the existing AC motor; the range of speed regulation is large and continuous, the effect of saving power is obvious;

• It is easy to realize the forward and reverse switching of the electric motor, and constitute automatic control system;

• Smooth start and low current, which can be suitable for frequent start-up and braking situations;

• Reasonable use of frequency conversion technology can reduce motor heating and abrasion level of the moving parts, and prolong the lifetime of motor and reduce the maintenance costs;

• Simple structure, safe operation, simple maintenance; It can be used in flammable, explosive and corrosive environment;

• Automatic switching between electricity and power saving status, automatic alarm, no impact on normal work.

Remote driving

The driver can remote drive the moving locomotive outside the locomotive.

Remote control

The driver can remote control the locomotive at the TBM terminal.

Auto timing

The moving speed of the locomotive can be automatically regulated according to the weight and gradient.

Anti-collision location

The precision of anti-collision location system is less than10cm. The locomotive can be automatically stopped duringbacking when barrier is detectedby obstacle perception system.

Video communication

The data of loading and unloading of the locomotive can be detected in time precisely.

Data transmission

The data of locomotive status and railway status can be collected and transmitted in time.

Turnout control

According to the position and operation scheduling of the locomotive, it can choose the right turnout.

Check and scheduling

The data of locomotive position and railway occupation can beprecisely detected and transmitted to the monitoring center. According to the data, tunneling operation can be optimized and scheduled perfectly.